Construction Dust

Construction dust can cause serious damage to your health and some types of dust can eventually kill you. Regularly breathing in these harmful dusts over a long period of time can cause a life threatening disease on your lungs. The dangers of asbestos dust is well documented elsewhere (see Asbestos health and safety on the HSE website) so we are focusing here on other types of dust which have harmful side-effects.

Construction dust can cause serious damage to your health and some types of dust can eventually kill you. Regularly breathing in these harmful dusts over a long period of time can cause a life threatening disease on your lungs. The dangers of asbestos dust is well documented elsewhere (see Asbestos health and safety on the HSE website) so we are focusing here on other types of dust which have harmful side-effects.

What is construction dust?

Construction dust is generally used to describe different types of dusts that you may find on a construction site. There are three main types of construction dust:

- Silica dust – created when working on materials containing silica. Materials such as concrete, mortar and sandstone (also known as respirable crystalline silica or RCS)

- Wood dust – created when working on softwood, hardwood and wood-base products like MDF and plywood

- Lower toxicity dusts – created when working on materials containing little or no silica. The most common materials include gypsum – plasterboard, limestone, marble and dolomite

Health Risks

Anyone who works on a construction site or with these types of dusts should know about the risks to their health. The main dust-related diseases are:

- Lung cancer

- Silicosis

- Chronic Obstructive Pulmonary Disease (COPD)

- Asthma

Some diseases such as advanced silicosis or asthma can come on quite quickly. However, most diseases take a long time to develop. The dust can build up in the lungs and harm them over time and the effects are not instantly obvious.

Unfortunately, by the time the effects have been noticed, the damage done may already be life-threatening and it may lead to a permanent disability and early death.

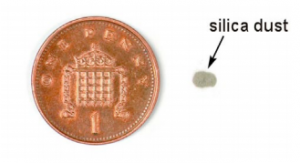

Construction workers have an incredibly high risk of developing these diseases. This is due to many common construction tasks creating high dust levels. Over 500 construction workers are believed to die from silica exposure every year. The amount of dust needed to cause this damage is not large. The largest amount of of silica someone should take in a day (after using the right controls) is shown left.

Construction workers have an incredibly high risk of developing these diseases. This is due to many common construction tasks creating high dust levels. Over 500 construction workers are believed to die from silica exposure every year. The amount of dust needed to cause this damage is not large. The largest amount of of silica someone should take in a day (after using the right controls) is shown left.

The Law

The Control of Substances Hazardous to Health Regulation 2002 a.k.a COSHH, covers activities, which may expose workers to construction dust.

There are three key things involving risks and controls that you need to carry out:

- Assess the risks

- Control the risks

- Review the controls

Assess the risks

Assess the risks that are linked to the work and materials. High dust levels are caused by one or more of the following:

- Task – the more energy the work involves, the bigger the risk. High-energy tools like cut off saws, grinders and grit blasters can produce a large amount of dust in a very short period of time

- Work area – an enclosed space will allow the dust to build up quicker. However do not assume that dust levels would be low if you work outside with high-energy tools

- Time – the longer the work takes, the more dust there will be

- Frequency – doing the same work daily will increase the risks

Control the risks

Using the follow measures will help you control any risk when working with construction dust.

Stop or reduce the risk

Before you start working, look for ways of stopping or reducing the amount of dust you might make. Use different materials, less powerful tools or other work methods.

Examples are:

- The right size of building materials which requires less cutting or preparation

- Silica-free abrasives, to help reduce the risks when blasting

- A less powerful tool – a block splitter instead of a cut-off saw

- A different method of work altogether – a direct fastening system

Control the dust

Control the dust

Even if you stop some dust by using this method, you may carry out other work that could product high dust levels. There are two ways of doing this:

- Water – Water dampens down dust clouds, however it needs to be used correctly. This means enough water supplied at the right level for the entire time that the work is being done. Just by wetting the surface/material does not work

- On-tool extraction - On-tool extraction removes the dust as it is being produced. It is a type of Local Exhaust Ventilation (LEV) system that is fitted directly onto the tool. The LEV system involves several parts – the main tool, the capturing hood, extraction unit and tubing. Use an extraction unit to the correct specification e.g. H (High) M (Medium) or L (Low) Class filter. Don't use a general commercial vacuum alone

Respiratory Protective Equipment (RPE)

Water or on-tool extraction may not always be the most appropriate choice of methods or they might not reduce the risk of exposure enough. Often RPE has to be provided as well. You will need to make sure that the RPE is:

- Adequate for the amount and type of dust – RPE has an assigned protection factor (APF) which shows how much protection it gives the wearer. The general level for construction dust is an APF of 20, meaning the wearer only breathes one twentieth of the amount of dust in the air

- Suitable for the work – disposable masks or half masks can become uncomfortable to wear for a long period of time. Powered RPE helps minimise this. Make sure you consider it when people are working for more than an hour without a break

- Compatible with other items of protective equipment

- The right size for the user. Face fit testing will be needed for tight-fitting masks

- Worn correctly. Anyone using tight-fitting masks need to be clean shaven

REMEMBER: RPE is the last line of protection. If you are just relying on RPE you need to be able to justify your reason for this.

Other Controls

Depending on what you are working on or with, you may have to combine these measures with other controls. Always think about:

- Limiting the number of people near the work

- Rotating those doing the task

- Enclosing the work top stop the dust escaping. Use sheeting or temporary screens

- General mechanical ventilation to remove dusty air from the work area

- Selecting work clothes at do not keep hold of dust

- Using equipment that won't spread dust such as roll container trolleys

You also need to make sure workers are carrying out the job in the correct way and are using the controls properly. As an employer you should make sure your employees are trained to:

- Know about dust risks and how this can their health

- Know how to use the dust controls and check that they are working

- Know how to use and look after RPE and other personal protective equipment (PPE)

- Know what to do if something goes wrong

Review (the controls)

Even though you might have all the right controls in place, but have you checked they are all working properly? Check the controls work by:

- Having procedures to ensure that work is done in the correct way

- Checking controls are effective. Does the work still seem dusty? You might need to carry out dust exposure monitoring

- Involving workers. They can help identify problems and find solutions

- Maintaining equipment

- Following instructions in maintenance manuals

- Regularly look for signs of damage. Make repairs

- Replace disposable mask in line with the manufacturer's recommendations

- Properly clean, store and maintain non-disposable RPE. Change RPE filters as recommended by the supplier

- Carry out a thorough examination and test of any on-tool extraction system at least every 14 months

- Supervising workers. Make sure they:

- Use the controls provided

- Follow the correct work method

- Attend any health surveillance where it is needed

You may have to put a health surveillance programme in place. You might need advice for this from an occupational health professional.

View The Workplace Depot's range of PPE Workwear

Posted in Health and Safety